Environmental Protection Painting Production System

The environmental protection painting production system is composed of agitating tank, high-performance bead mill, storage kettle, paint mixing kettle, delivery pump, forced cooling unit, connecting pipelines, etc. The slurry is transmitted from the agitating tank to the bead mill for grinding through the quantitative delivery pump. The ground slurry is then transported to the storage kettle where the qualified slurry is ready to fill or go to the next process and the unqualified slurry is sent back to the mill for further grinding. After one or several times of operation, operating parameters of the whole equipment can be determined and automatic production can be realized.

Through the optimized system configuration, energy is transferred to the grinding media to the greatest extent. Special technology adopted by this equipment allows large material flow. This not only achieves the purpose of grinding materials within a short period but also causes small rise in the temperature of the material, thus effectively controlling the temperature rise of the overall equipment. The forced cooling unit takes away the heat as much as possible, preventing the material from discoloring or agglomerating.

Multiple monitoring devices are adopted, and the data are collected by the PLC and transferred to the industrial control computer or touch screen. Operators can monitor the whole equipment through the computer conveniently, making our product suitable for the grinding of materials which has strict requirements of explosion protection and human protection.

This environmental protection painting production system can independently complete the whole process of dispersing, grinding, filtering, automatic suction and semiautomatic filling. We provide multiple types of this product with the annual output of 800 tons, 1800 tons, 4800 tons, 8800 tons, 11000 tons, 18000 tons, 28000 tons, 58000 tons, 88000 tons, etc. According to the actual production needs of customers, professional products can also be made.

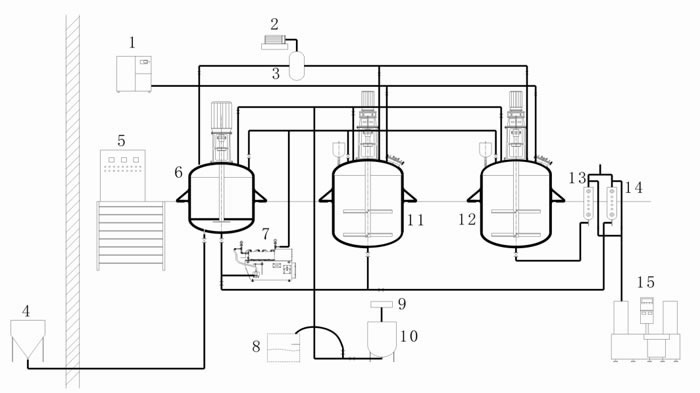

Flowchart of the Painting Production System

1. Air Compressor

2. Vacuum Pump

3. Vacuum Buffer Tank

4. Powder Suction Tank

5. Circuit Control System

6. High-speed Pre-dispersing Kettle

7. Horizontal Sand Mill

8. Liquid Suction Tank

9. Liquid Meter

10. Additive Tank

11. Allocating Kettle

12. Allocating Kettle

13. Recoil Type Bag Filter

14. Recoil Type Bag Filter

15. Filling Machine

As a specialized environmental protection painting production system manufacturer and supplier in China, we offer a broad range of products, including agitated bead mill, sand mill mechanical seal, stainless steel reactor, and more.

Related Names

Coating Production Line | Green Paint Production Line | Environmental Assembly Line | Painting Equipment