WP Formulation Jet Milling and Mixing System

This jet mill and mixing system for agrochemical perfectly integrates our mature jet mill technology, mixing technology and intelligent control technology. It can meet the special process requirements of milling and mixing of various pesticides. Through special design, there is no dust flying during the working process, which meets the requirements of environmental protection.

Specifications| Model | QYF-150 | QYF-260 | QYF-400 | QYF-600 | QYF- 720 |

| Production Capacity(kg/h) | 5-100 | 50-200 | 80-380 | 200-500 | 400-1000 |

| Air Consumption(m3/min) | 3 | 6 | 10 | 20 | 40 |

| Working Pressure(MPa) | 0.75-0.85 | 0.75-0.85 | 0.75-0.85 | 0.75-0.85 | 0.75-0.85 |

| Feed Diameter(mesh) | 60-325 | 60-325 | 60-325 | 60-325 | 60-325 |

| Grinding Size(μm) | 0.5-30 | 0.5-30 | 0.5-30 | 0.5-30 | 0.5-30 |

The whole system is remote controlled by the touch screen. Materials are transported by the negative pressure air flow and the draught device installed in the feeding port ensures no dust flying. The double spiral mixers guarantee sufficient and even mixing. The milling process uses the fluidized bed jet mill principle with high working efficiency and the particle size distribution is uniform. In addition, the discharge outlet can be directly connected to an automatic packaging machine.

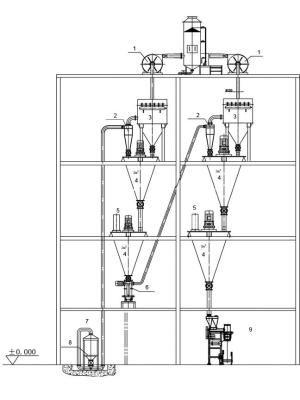

Flowchart of the Jet Milling and Mixing System for Agrochemical

A. Continuous model, applied to mass production

1. Draught Fan

2. Cyclone Separator

3. Dust Collector

4. Mixer

5. Filter

6. Jet Mill

7. Batching Area

8. Feeding Device

9. Packaging Equipment

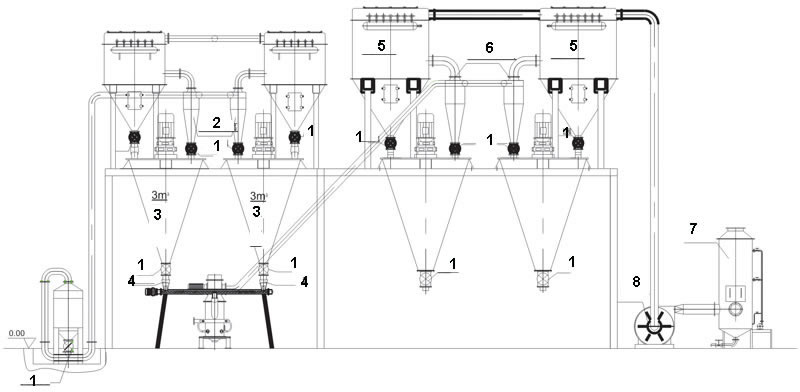

B. Continuous model, applied to mass production

2. Cyclone Separator

3. Mixer

4. Flexible Connection

5. Dust Collector

6. Cyclone Separator

7. Water Film Scrubber

8. Draught Fan

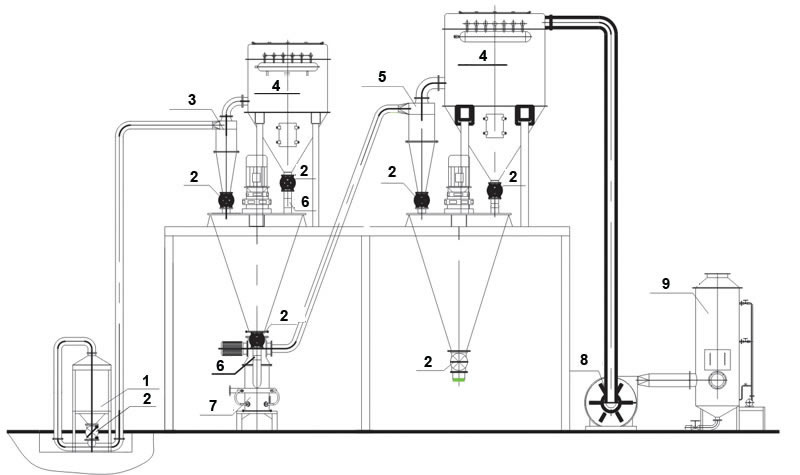

C. Simplified model, applied to small batch production

2. Outlet Valve

3. Cyclone Separator

4. Dust Collector

5. Cyclone Separator

6. Flexible Connection

7. Jet Mill

8. Draught Fan

9. Water Film Scrubber

Miyou Group is a specialized jet mill and mixing system for agrochemical manufacturer and supplier in China. Apart from jet mill system, we also offer sand mill, bead mill system, special seal for sand mill, reactor, Air Classifier System, and more.

Related Names

Mixed Crushing System | Intelligent Control Mill and Mixer | Multifunctional Milling Machine | WP Production Equipment