Jet Mill System

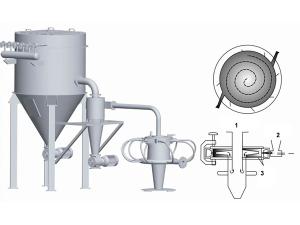

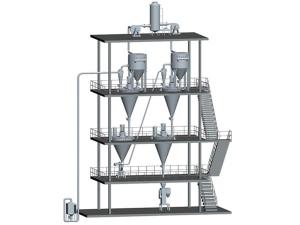

The jet mill system is composed of jet mill, cyclone separator, dust collector, draught fan and other parts. After filtering and drying, the compressed air is jetted into the milling chamber through nozzles. Materials are crushed by the continuous collision, friction, and shearing at the meeting point of multi-strand high-pressure air flow.

Under the action of the draught fan, the crushed materials move with the updraft into the grading area where the coarse and fine materials are separated by the strong centrifugal force produced by the grading turbines rotating at a high speed. Fine particles meeting the size requirement move into the cyclone separator and are collected by the dust collector. The coarse particles descend into the milling chamber for further grinding.

Our jet mill system is suitable for the dry grinding of various materials, especially those with high hardness, high purity, and high added value. Unlike the mechanical grinding finished by the impact from blade or hammer, the pulverization process of the jet mill is completed by the collision between materials themselves, so the crushed materials have high purity and the abrasion of equipment is small. The grinding is conducted in a confined environment, so there are little dust and low noise, which is clean and environmentally friendly. Program controlled, our product is easy to operate.

As a specialized jet mill system manufacturer and supplier in China, Miyou Group offers a wide range of products, including sand mill, bead mill system, Air Classifier System, reactor, Reactor Using Mechanical Seal, and much more.

Related Names

Pneumatic Cracker | Material Pulverizing Equipment | Gas Crusher | Milling | Grinding