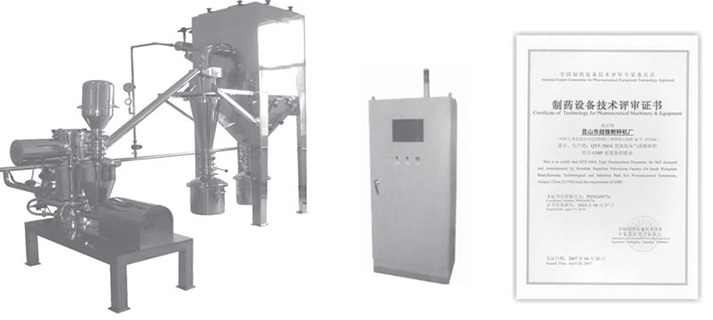

GMP Certified Jet Mill Unit

This GMP certified jet mill unit applies to the ultrafine pulverization of various cosmetics, Chinese medicine, western medicine, health care products, etc. The material is crushed by the expanded gas and the temperature will not rise, making our product suitable for the grinding of sugary, volatile, heat-sensitive, and low melting point materials.

Specifications| Model | QF-148 | QF-248 | QF-348 | QF-488 |

| Production Capacity (kg/h) | 5-100 | 50-200 | 80-380 | 200-500 |

| Air Consumption(m3/min) | 3 | 6 | 10 | 20 |

| Working Pressure (MPa) | 0.8-1.5 | 0.8-1.5 | 0.8-1.5 | 0.8-1.5 |

| Feed Particle Size (mesh) | 60-120 | 60-120 | 60-120 | 60-120 |

| Grinding Size(μm) | 0.5-30 | 0.5-30 | 0.5-30 | 0.5-30 |

| Installed Power (kw) | 40 | 60 | 95 | 188 |

Adopting the domestic initiative and international leading automatic intelligent control system, the precise control of the grinding process can be realized, ensuring narrow and uniform particle size distribution. Powder particles with the size of 0.5-30nm can be produced because of the large impact caused by the high-speed gas flow.

Our product is specially designed to prevent oil from entering. The inert gas undergoes three levels of filtration which are rough filtration, precision filtration and sterilization filtration. The pulverization is completed by the collision of material particles. All these factors make the pulverization process pollution-free. In addition, this jet mill unit has a simple structure. Its inner and outer walls have high finish, and there is no dead angle, which facilitates cleaning.

Jet Mill Unit Certified by GMP

Fully Automatic Control Cabinet with Touch Screen

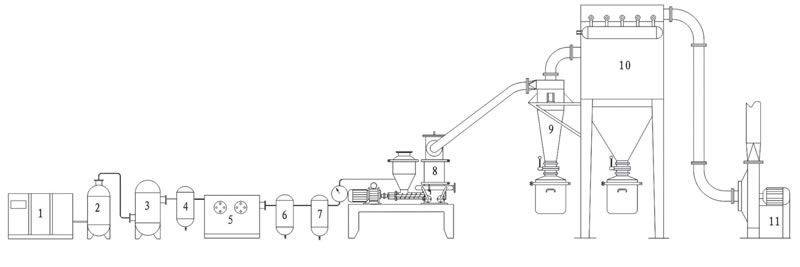

Flowchart of the GMP Certified Jet Mill Unit

2. Air Tank

3. Oil Remover

4. Rough filter

5. Air Freeze Dryer

6. Precision filter

7. Sterilization filter

8. Jet Mill

9. Cyclone Separator

10. Dust Collector

11. Draught Fan

As a specialized GMP certified jet mill unit manufacturer and supplier in China, we provide not only jet mill system, but also Air Classifier System, metallic nanometer powder, bottom agitating mechanical seal, and sand mill, among others.

Related Names

Good Manufacturing Practice Requirement | High Quality Jet Mill | Jet Mill with GMP Standard