Ultrasonic Jet Mill

The ultrasonic jet mill is widely used for the superfine grinding of various materials, such as carbendazim, thiophanate, herbicide, silica, pigment, dye, nimodipine, cortisone, etc., in pesticide, chemical, metallurgical, western medicine, traditional Chinese medicine, and other industries.

Specifications| Model | QYN 200 | QYN400 | QYN600 |

| Production Capacity (kg/h) | 30-100 | 100-300 | 300-600 |

| Air Consumption (m3/min) | 6 | 10 | 20 |

| Working Pressure(MPa) | 0.7-0.8 | 0.7-0.8 | 0.7-0.8 |

| Feed Diameter(mesh) | 60-325 | 60-325 | 60-325 |

| Grinding Size (μm) | 5-45 | 5-45 | 5-45 |

| Installed Power (kw ) | 45 | 75 | 160 |

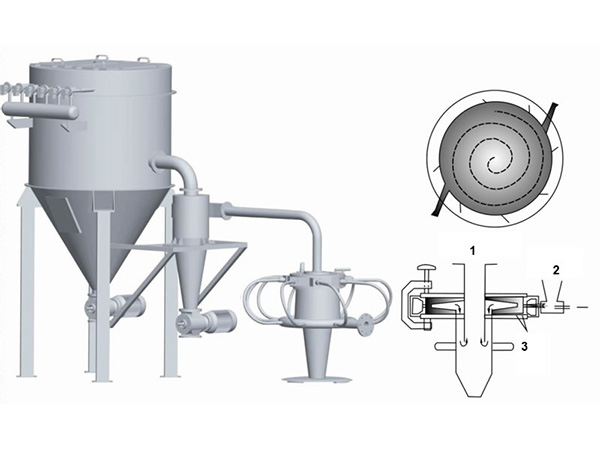

After entering into the grinding chamber, the unprocessed materials are struck by the ultrasonic air flow jetted by the multiple nozzles in the periphery of the grinding chamber. The powder particles collide with each other and smash. Coarse particles are separated by the grading room and sent back to the grinding chamber for further grinding. At last, uniformly distributed superfine powder can be obtained in the outlet.

Because of the high impact speed which is over 2.5Mach, particles with the size of one to ten microns can be easily acquired. During the grinding process, the compressed air expands, making temperature reduce. Therefore, our ultrasonic jet mill is suitable for the milling of heat-sensitive and low melting point materials. Mixing and dispersing can also be achieved during grinding. In addition, there is little noise and no vibration during working.

With high pulverization efficiency, this equipment can conduct continuous milling and the purity of the finished products can be guaranteed. Simple in structure and small in volume, our product is easy to maintain.

QYN Ultrasonic Jet Mill

2. Materials

3. Liner

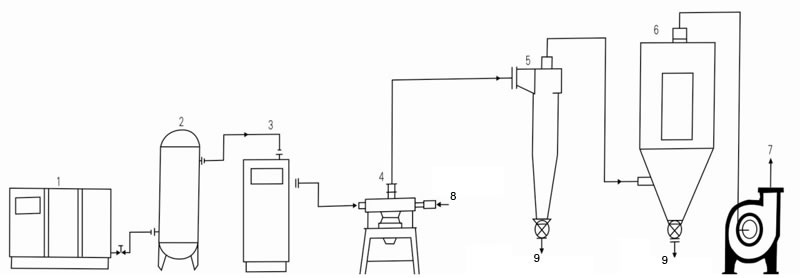

2. Air Tank

3. Air Freeze Dryer

4. QYN Ultrasonic Jet Mill

5. Cyclone Separator

6. Dust collector

7. Draught Fan

8. Finished Products

9. Materials

As a professional ultrasonic jet mill manufacturer and supplier in China, Miyou Group also provides agitated bead mill, Vertical Air Classifier, stainless steel reactor, nanometer tin powder, and more.

Related Names

Supersonic Jet Mill | Supersonic Airflow Grinding Unit | Jet Pulverizer