SC Formulation Plant Milling and Mixing System

The SC formulation plant milling and mixing system is suitable for the material grinding in paint, coating, printing ink, farm chemical and other industries. Easy to operate, it has high efficiency and good reliability. The optimally designed dispersing disc makes the grinding media collide and rub intensely, thus obtaining materials with desirable fineness in a short period of time.

Specifications| Mode | MYM15A | MYM20A | MYM30A | MYM48A | MYM60A |

| Tank Volume (L) | 15 | 20 | 30 | 48 | 60 |

| Motor power (KW) | 11 | 18. 5 | 22 | 37 | 45 |

| Production Capacity (kg/h) | 30-200 | 40-300 | 50-600 | 100-1000 | 150-1200 |

| Fineness (μm) | 2-20 | ||||

| Pump Type | Diaphragm pump/Gear pump | ||||

Due to the adoption of the dynamic separation technology, the grinding media and the slurry can be effectively separated. This enables our product to use ultrafine grinding medium (Φ0.5mm-Φ1.4mm), so the number of the beads can be increased geometrically. The specially designed separation device has a long lifespan and it almost needs no maintenance.

As the formulating unit of the mechanical seal technology conditions for sand mill or bead mill, our company has configured an optimally designed mechanical seal for this milling and mixing system, enabling it to have high reliability and excellent abrasion resistance. Pollution to the ground material can be eliminated by adopting the cooling liquid compatible with the ground material.

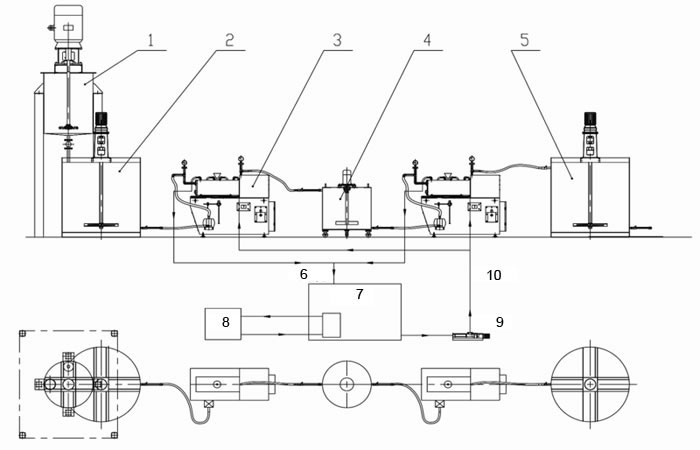

Flowchart

1. Pre-dispersion Tank

2. Raw material Tank

3. Sand Mill

4. Filtering Tank

5. Finished Product Tank

6. Chilled Water Coming Out

7. Circulating Water Tank

8. Refrigerating Machine

9. Circulating Pump

10. Chilled Water Entering

Our company is an experienced SC formulation plant milling and mixing system manufacturer in China. We also provide horizontal sand mill, stainless steel reactor, ultrasonic jet mill, pump using mechanical seal, and much more.

Related Names

Grinder and Mixer | Mill and Mix Equipment | Multifunctional Device | SC Formulation Equipment